ABERLINK 3D

ABERLINK 3D

Description

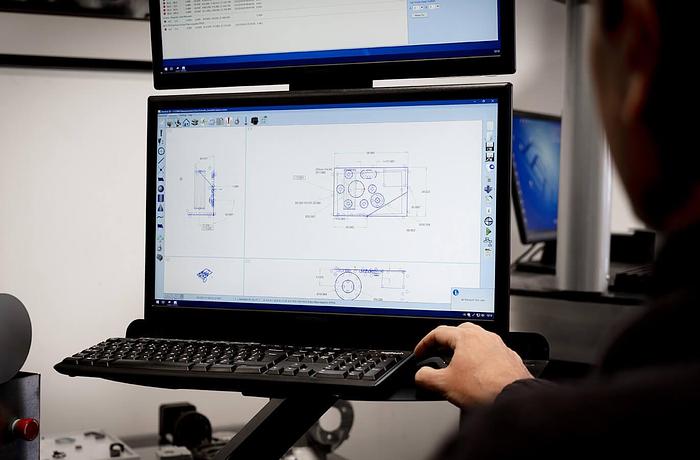

Aberlink 3D is an innovative software package designed for manual and CNC CMMs. It is also the software of choice for numerous other manufacturers of measuring devices.

Now popular throughout the world, Aberlink’s revolutionary measurement software provides the user with a powerful, yet easy-to-use user interface. This substantially increases component through-put and vastly reduces the learning period of new users. Watch the video and see for yourself.

Manchester Metrology has seats available for hire or purchase.

OVERVIEW

The whole philosophy for Aberlink is to make measurement easy. Aberlink 3D software has been written by engineers for engineers and sets the industry standard for simple-to-use software. Designed around a graphical interface, Aberlink 3D can work in 2D or 3D, on manual or CNC CMMs and is equally at home when used with either touch, scanning or vision systems. It is easy to understand why Aberlink 3D has become the software of choice not only for Aberlink, but for numerous other manufacturers of measuring devices around the world.

Aberlink 3D software is not only ahead of its competition in being the industry standard for ‘easy-to-use’ software, but also has the depth of functionality to make it the choice for either occasional users or full-time inspection professionals.

Aberlink 3D software is revolutionary. For example, Feature Predict enables you to just take measurement points and the software automatically determines if you are measuring a Plane, Line or Circle feature. Move from feature to feature and the software predicts what you are measuring. As a component is measured a representation of it is built up on the screen. The user simply clicks on the measured features to call up dimensions exactly as they would appear on a drawing.

Inspection reports can be in the form of fully dimensioned graphical representations as created on the screen, or tabulated reports in various formats that can show nominals, tolerances, errors, pass/fails, geometric tolerances etc. These reports can also be output to an Excel spreadsheet.

Further reports are available to show the form of features (roundness, straightness etc.), hole or point positions, or complete batch results on one report. The user’s company name also appears on all outputs.

Every time a component is inspected, a programme for measuring subsequent components is automatically created. The software also calculates ‘safe’ moves between features, even when the probe is indexing – just another thing that the operator doesn’t have to worry about.

FEATURES

Feature Inspection

• Automatic measurement routines

• Powerful interactive graphics window

• Automatic feature recognition

• 2D and 3D inspection

• Geometric feature inspection

• Free form curve inspection

• DXF data import/export

• STEP and IGES export

• Feature construction

• Intelligent feature projection

• GD&T dimensions and tolerances

• Digital Read Out (DRO)

Report Formats

• Engineering drawing GD&T report

• Simple PASS/FAIL report

• Form plots

• Batch summary report

• Tabulated reports

• Graphical fly-out labels

• Drag & drop reporting

• Real-time SPC

• Combine multiple views

• Export to Excel

• Historical data reporting

Programme Tools

• Teach & repeat programming

• Drag and drop programme editor

• Run programs from any point

• Measure a subset of features

• Simple object-based programming

• No complex programming language

• Automated batch inspection

• Password protect programmes

• Automatic safety moves

• Feature replicator

Supported Machines

- Manual and CNC machines

- CMMs

- Vision measuring systems

- Portable arms

- Video inspection machines

- Profile projectors

- Supported Probes

- Manual probe heads

- Automated probe heads

- Rigid probes

- Motorised probe head

- Change racks

- Touch trigger probes

- Vision and video probes

Specifications

| Condition | New |